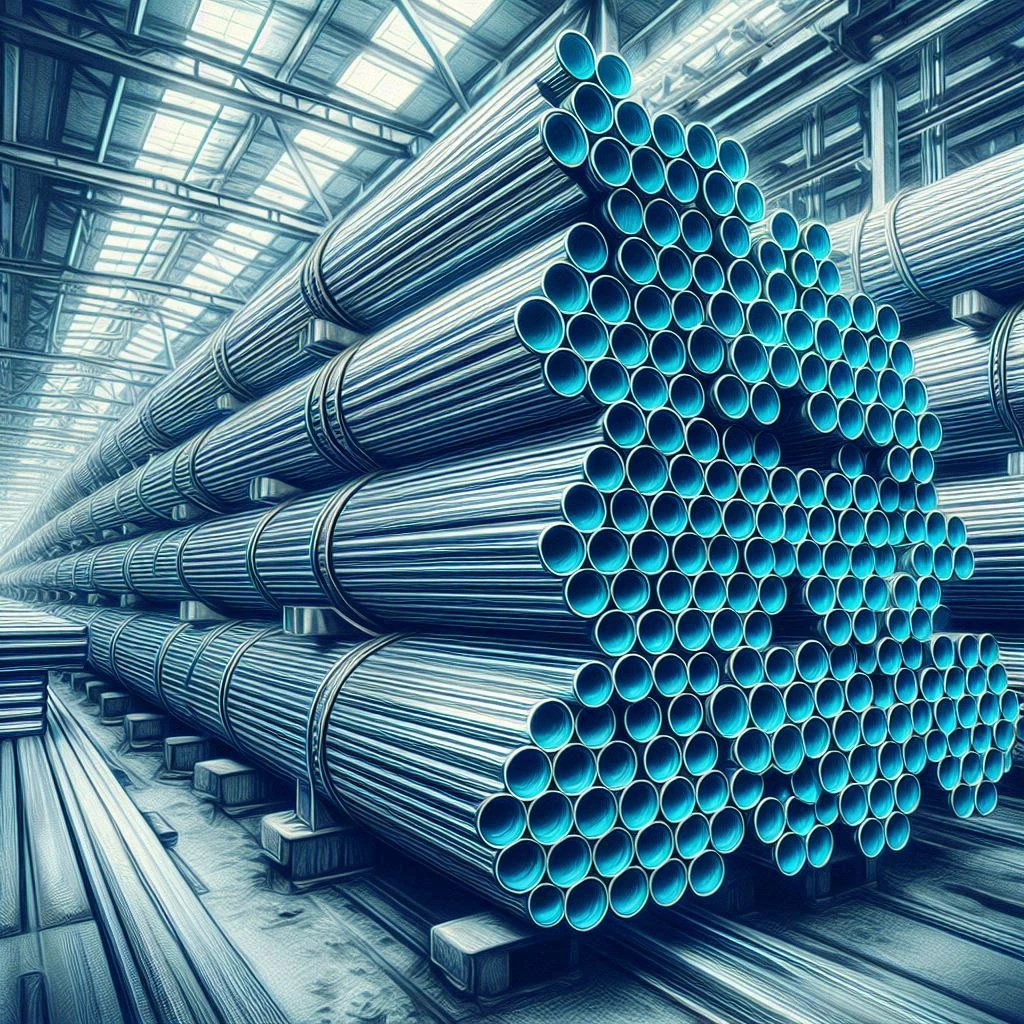

Product description and technical details of our Standard GI Pipe

| Specification | Details |

|---|---|

| Base Material | Iron (Fe) |

| Alloying Elements | Carbon, Manganese, Silicon, Sulfur |

| Galvanization Coating | Zinc |

| Pipe Wall Thickness | 1.2 mm to 10 mm (depending on size and application) |

| Diameter | 15 mm (1/2 inch) to 150 mm (6 inches) or customized |

| Tensile Strength | 350 to 550 MPa |

| Yield Strength | 200 to 350 MPa (depends on diameter) |

| Elongation | 20% to 30% in standard test specimen |

| Hardness | 150 to 200 HB |

| Thermal Conductivity | 50 to 60 W/m·K |

| Chemical Resistance | Good resistance to many chemicals |

| Thermal Expansion Coefficient | Approximately 12 to 14 × 10⁻⁶ /°C |

| Length | 6 meters (approximately 20 feet), customizable |

| Weight per Meter | Varies with diameter and wall thickness |

| Surface Finish | Hot-Dip Galvanization |

Features

- Crafted for superior impact resistance, ensuring dependable performance even in high-stress environments.

- Engineered with precision for a flawless, smooth internal surface that optimizes fluid flow.

- Designed to maintain structural integrity under both high and low temperature extremes.

- Incorporates innovative manufacturing processes for enhanced mechanical properties and longevity.

- Boasts advanced resistance to abrasion, ensuring durability in rugged and demanding applications.

Reviews

There are no reviews yet.